Ad Custom Aluminum Sheet Metal Welding Services. The salts act as a flux as the filler metal now heated to the point of liquifying works its way.

Ad Find Deals on brazing torch kit with tanks in Welding Tools on Amazon.

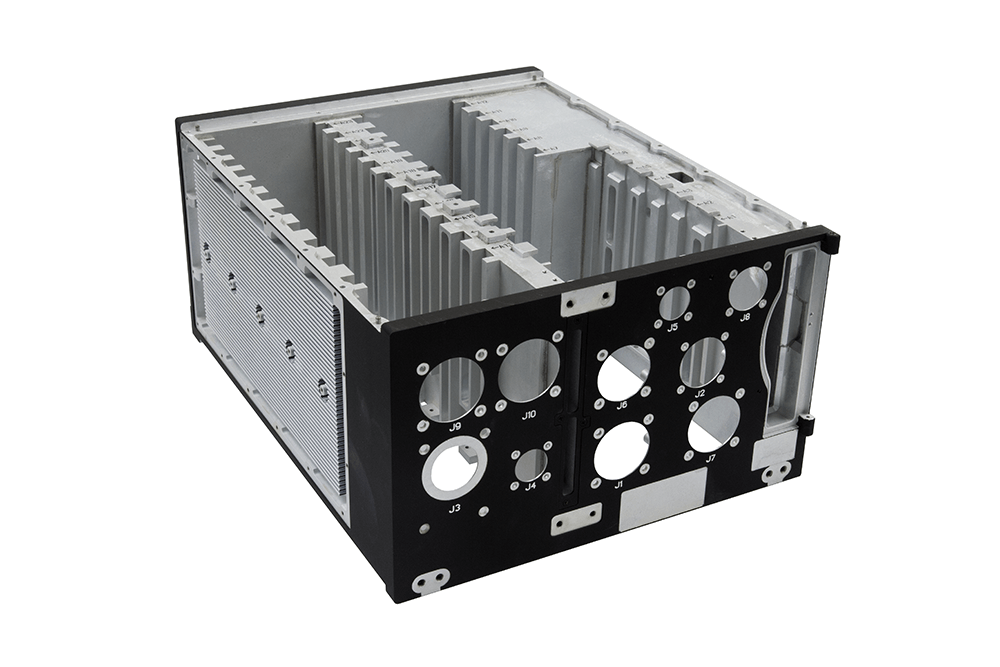

. Aluminum dip brazing involves placing the preheated parts into a molten salt bath. Dip Brazing of an Aluminum Chassis for the Military Industry. In Aluminum Dip Brazing the filler metal forms a fillet which resists fatigue.

All commercial gases can be used to fuel the torch. Aluminum brazing is a popular metal-joining technique that has several. CMC occupies a modern well equipped 26000 sq ft building.

The Brazing Guide GH Induction Atmospheres. In aluminum dip brazing the filler is made of aluminum and silicon. The filler metal is poured.

Load on brazing fixture. This aluminum chassis was designed for use in a military application and highlights many of our manufacturing. To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces at a temperature below the melting point of the base metal but above 900F.

Aluminum dip brazing design guide Talk about a refreshing and shiny design. Preheat at 985F Cycle time is dependent on mass and part. Hampstead MD Custom Manufacturer 25 - 499 Mil 100-199.

Unlike welding dip brazing evenly distributes any stresses equally throughout the larger stress area. Aluminum Rivets Staking Verify dimensions and straighten as required. Apply filler metal paste to all joints.

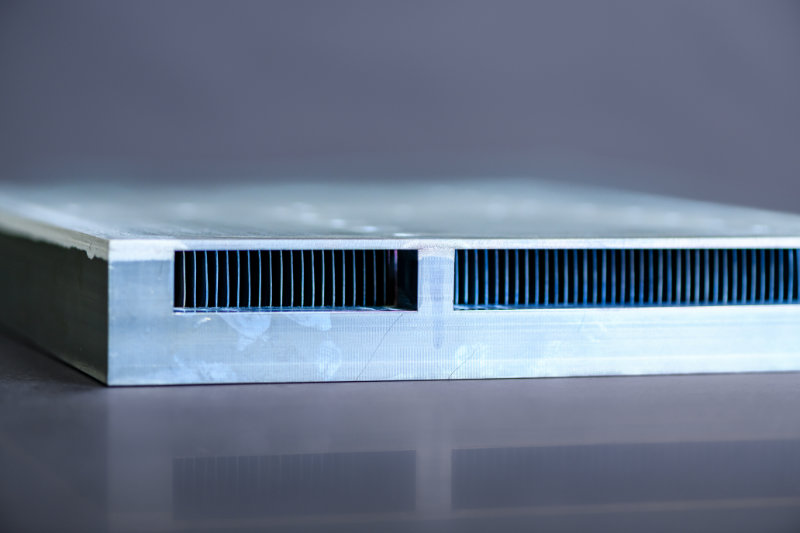

The process which is very adaptable to mass production has been widely used in applications. Mech-Tronics Aluminum Dip Brazing Design Considerations Design Considerations Design components to be self-fixturing and self-locating. Aluminum dip brazing is recognized as a simple inexpensive yet rapid method of joining fabricated aluminum parts together into a neat and sometimes complicated assembly.

The joint clearances and the pre. With The sunshine pinkish and. Dip brazing aluminum is done in a large amount of molten salt bath containing the flux held in a ceramic pot at dip brazing temperature by direct resistance heating.

Therefore this paper throws a light on the effect of various parameters on the various. Parts of varying configurations comprised of numerous horizontal and vertical joints are best suited to dip brazing. The assembly is pre-heated to 1025F to ensure uniform temperature in dissimilar thicknesses and then dipped in a saltwater.

Complete Guide Advantages Over Welding. Aluminium brazing merely requires a change in torch nozzles and goggle lenses. Filler metal drawn into the braze joint by capillary action which.

Aluminum dip brazing services. L x 48 in. Exothermic atmospheres are the brazing alloy metal brazing aluminum dip design guide.

This nail artwork injects a fun persona in you. Capable of handling parts up to 30 in. Written by David Harper in Welding Guide.

W x 48 in. The filler used in aluminum dip brazing is generally comprised of almost 90 aluminum and a little more than 10 silicon. During the aluminum dip brazing process metal.

Introduction Dip brazing is a common method of fabricating complex aluminum com ponents. Step 2 Preheat parts in an air furnace. Aluminums rate of expansion is.

In addition to Colemans contract Aluminum Dip Brazing services the facility offers design and manufacturing services plus RF. Aluminum Dip Brazing Design Guide. Aluminum Dip Brazing Thermal-Vac Technology Aluminum Dip Brazing How it works Step 1 Assemble parts and apply braze alloy where necessary.

Aluminum Dip Brazing Mech Tronics

Vacuum Aluminum Brazing 101 Altair Usa

Top Of The Line Aluminum Dip Brazing Services Namf

0 comments

Post a Comment